Painting

Inspection equipment

Each stage in the process of surface treatment is critical in guarding against premature coating failure. There are many tests and safeguards which can be put in place to ensure that the interaction of the substrate to the coating is as intended. The SGS Inspection Equipment range breaks down the process of inspection into six distinct steps - each step requiring certain pieces of equipment.

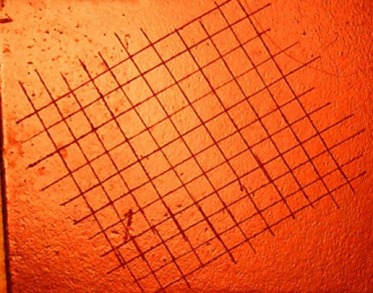

Grit 18

Aluminum oxide

Mk

Mk

Aluminum oxide 100